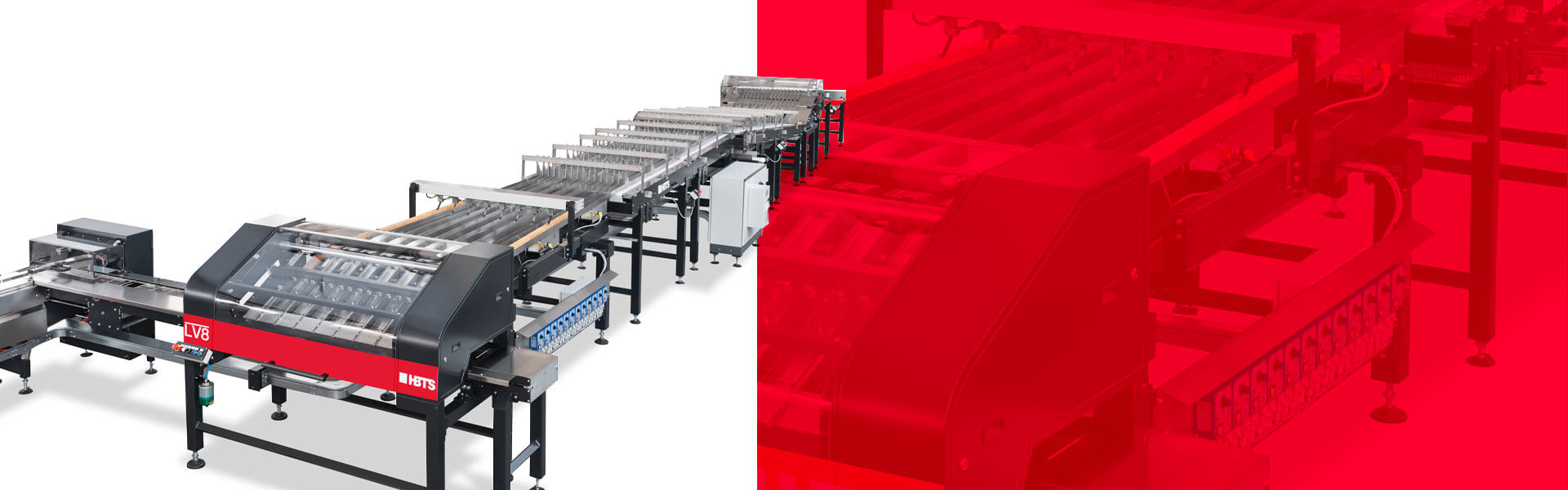

The LV Series is a program of multiplane’s metering loaders for the measuring and delivery of biscuits, crackers and similar products in slug’s formats.

Primarily used as terminal of automatic multilane products handling systems the LV is typically connected to the upstream line by means of multilane vibratory feeders with products standing on edge and in contact.

This servo loader automatically measures the length of the product’s dose and gently deposits onto an infeed cross chain connected to any flow or xfold wrapper for further packaging operations.

The LV loaders are suitable also to deposit slugs of products in trays providing they are indexed in the cross chain. The individual lanes braking system by grippers holds the incoming production flow to allow smooth slug’s dropping operation.

For integration purposes on any existing automatic lines or for semiautomatic applications the LV loaders can be supplied as stand-alone units with own electric board and HMI panel.